Drawer Construction

All of our drawers share a similar box construction with mortise and tenon joints; which can be faced with any of our 6 styles. The mortise and tenon joint was found to be the strongest joint according to www.finewoordworking.com's poll. Each drawer box contains four such joints. The drawer parts are cut by our computer controlled router built by Shopbot Tools.

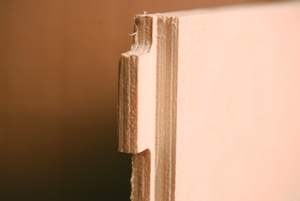

The side of each drawer box has tenons on both ends (pictured above). Which fit into mortice on the front and back panels (pictured right) of the box. Once the parts are sanded for a tight fit, they are glued and nailed together.

Once the box is built, the a 1/4" thick plywood bottom is inserted into a groove cut into the box. This ensures that the drawer will hold its contents securely.

After the box is finished the facing is applied to match the desired style. Then full extension metal drawer runners are installed. This hardware is designed to hold file drawers, but we use it for all our drawers to be sure they stand the test of time.